Правильное техническое обслуживание имеет важное значение для обеспечения длительной безаварийной работы и нормального электроснабжения генераторных установок.. Поэтому, все пользователи должны выполнять регулярное техническое обслуживание своих генераторных установок в соответствии со следующими этапами и содержанием..

В качестве примера рассмотрим дизель-генераторную установку., перед каждым запуском, очистить поверхность устройства, проверить уровень охлаждающей жидкости в бачке для воды, убедитесь, что сердцевина радиатора и интеркулер не заблокированы, проверьте воздушный фильтр на предмет засоров, проверить уровень масла в дизельном двигателе, и проверьте надежность электрических соединений в системе управления..

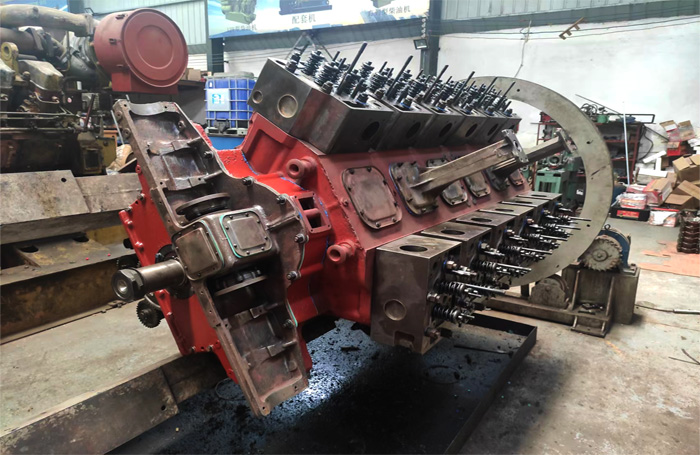

После каждой операции, внимательно проверьте и затяните все болты на вращающихся деталях, особенно те, которые подключают ТНВД, водяной насос, шкивы, и вентилятор. Также затяните фундаментные болты., проверить на утечки, и при необходимости прочистите все утечки. Очистите фильтрующий элемент воздушного фильтра от пыли., проверить уровень масла в двигателе, уровень ТНВД, и уровень охлаждающей жидкости в бачке для воды, и проверьте надежность электрических соединений в системе управления..

Помимо вышеперечисленных операций, регулярные проверки и замену легко изнашиваемых деталей и расходных материалов должны выполнять профессионально обученные специалисты.. Процедуры технического обслуживания и ремонта могут незначительно отличаться в зависимости от модели генераторной установки.; пожалуйста, обратитесь к прилагаемому руководству по эксплуатации.

Wate Group может похвастаться профессиональной технической командой и обширным опытом ремонта и обслуживания дизельных и газогенераторных установок.. Мы можем более эффективно и результативно решать различные проблемы с генераторными установками для наших клиентов., и предлагаем широкий ассортимент запчастей и расходных материалов для генераторных установок по конкурентоспособным ценам..

Вате (Шаньдун) Компания «Энергетические технологии», ООО

Вате (Шаньдун) Компания «Энергетические технологии», ООО